The push-button modules are an interesting application of the modular concept at the heart of the Helvest FleX system, and have received considerable interest.

In fact, with this module it is possible to control accessories not only digitally, but also with pushbuttons, so it is an interesting solution to have a small (or large) control panel for convenient manoeuvring away from the control unit and to combine the advantages of digital with those of a practical control panel.

For the more attentive and interested users, let us see in more detail how these modules work with DCC.

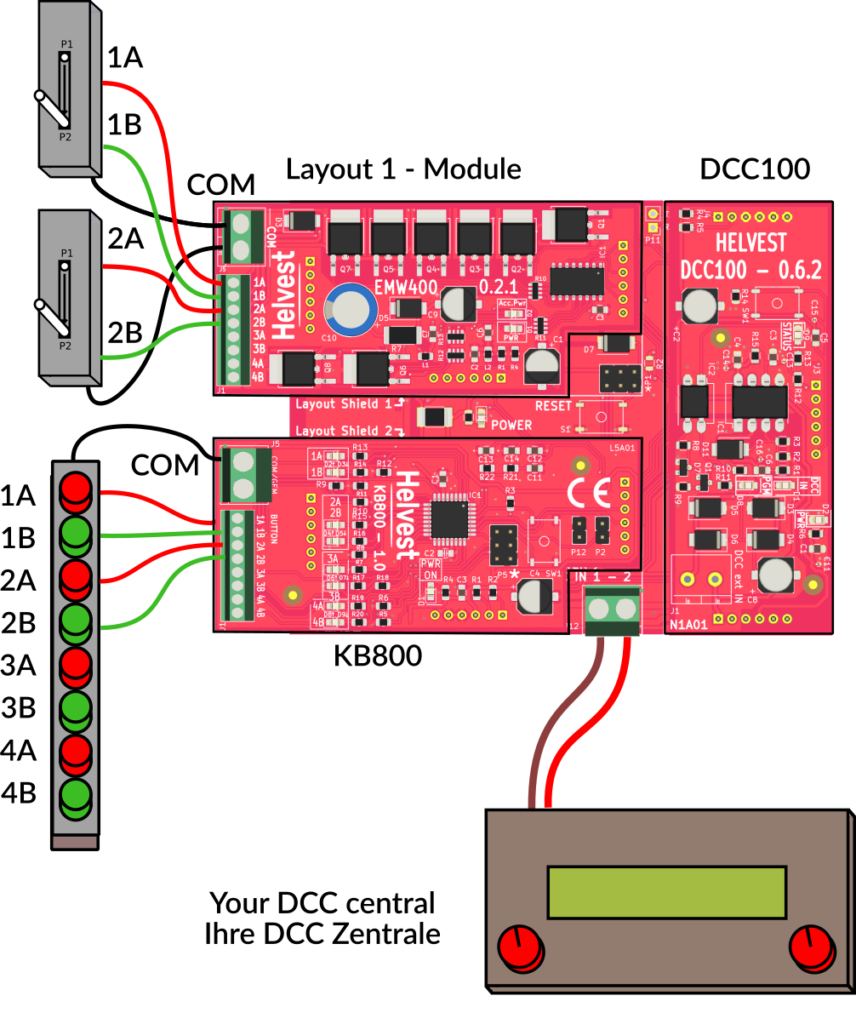

Assembly of a decoder with KB800 in DCC:

Unlike MVnet operation, in DCC the KB800 module must always be assembled in this way:

– HP100 motherboard

– DCC100 or DCC100-E digital readout module

– a Layout module that controls accessories (switches, signals, motors, etc.)

– KB800 or KB800-L module.

how buttons and accessories are connected

In DCC, the KB800 module (or KB800-L) is connected in a very immediate way to the accessories it must pilot, being installed on the same HP100, and the link between accessories is automatic: button 1 activates accessory 1, button 2 activates accessory 2, and so on.

The accessories can be controlled indifferently from the control unit or from the push buttons, as we know: it is the HP100 that tells the accessory to move, regardless of whether the command comes from the control unit or from the push button. The effect is the same.

In this example, two motors are connected to the ‘Layout 1’ module. Four buttons are correspondingly connected to the KB800. The motors can be moved with the control unit or the buttons.

Do I have to programme the KB800 (or KB800-L) module?

No. The module does not require programming: it does not connect to the DCC network, but communicates via the HP100 directly with the accessories that you decide to move with the push-buttons. The digital control unit is not ‘aware’ of its existence and has no influence on it.

Switching times, addresses, and other adjustments only affect the accessory module you are using. Therefore, the KB800 (and KB800-L) module does not require an address or CV.

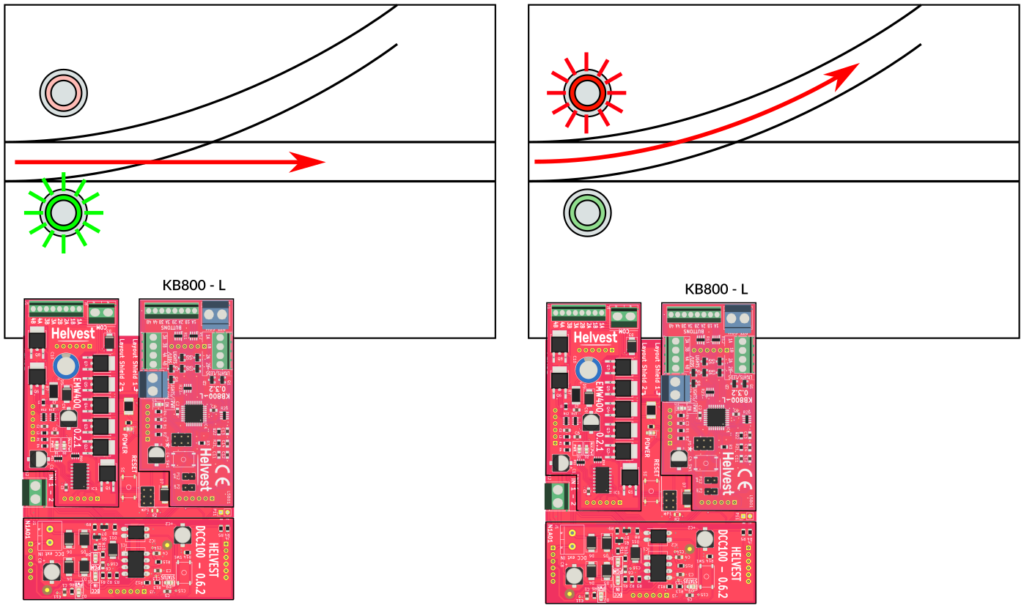

If you use the KB800-L module, which also operates lights, these lights switch together with the accessory, without the need for a specific address. For example, if you operate a switch with address 67, the indicator lights connected to the KB800-L switch both when you operate the switch and when you operate address 67 from the digital control unit, without the need for programming.

The KB800-L module also operates LEDs or small indicator lamps, but the address is not needed: it is the same as the accessory at the side.

Operating the buttons while moving

An important precaution with button operation is to make sure that the accessory is not in a state of motion. To protect both the accessory motor and the module, if a motor is moving, and you press the button to operate it in the opposite direction, the command is ignored. To move it in the opposite direction, you must wait until the movement is finished.

For example, if you are moving the tongue of a turnout from position A to position B, and you change your mind by pressing “A” while the needle is still moving, this command is disregarded and the turnout moves to position B. On the other hand, for a turnout to start a movement and switch back halfway through is something that does not happen in reality.

So wait until the movement is complete before pressing the button to bring the switch back.

So should I program the KB800 or the KB800-L?

The answer is: in DCC no, because it automatically connects with the module next to it.

In MVnet, on the other hand, you can also operate with the button devices on any other board. But this will be the subject of another article.